Single Axle Weighbridge :

Axle weighbridges are a very good choice for Mines and Factories, where installations are required to be quick. Shifting axle weighbridge can be done quickly and needs only a small pickup truck for transportation.

Axle weigh bridges are very cost effective solution, the user benefits from the low equipment cost, low cost of civil work & installation and hence rapid recovery on investment.

Civil work takes only 3 to 4 days time and the installation can be done in just one day. With its many advantages and cost benefits, axle weighbridge is highly rewarding solution with no compromise.

Feature

- Quick delivery and installation

- Low Cost

- Very low cost on civil work

- Installation in one day

- Powerful software (AXSOFT) which gives total control and accountability

- IP-68 protection for load cells

- System fully protected from lightening

- Rugged instrumentation to give seamless performance

- Capacity up to 60 Ton

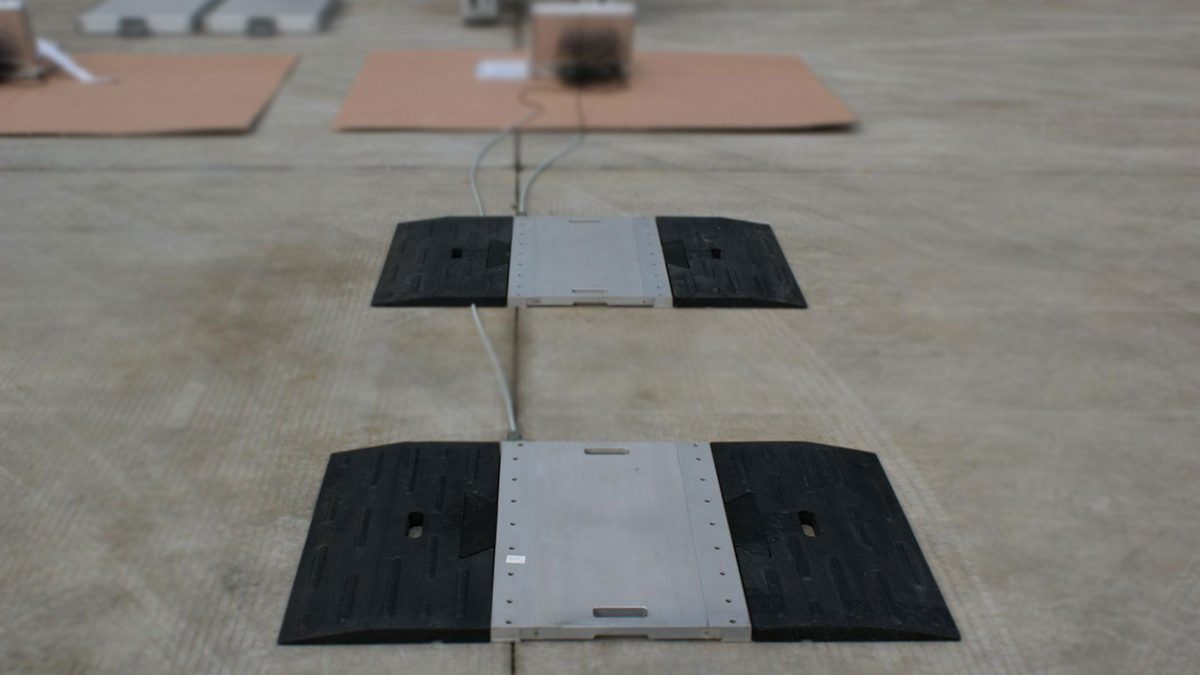

Portable Weigh-Pad

- Rated capacity: up to 20 ton per pad @ 20 lb graduations

- Material: High strength aluminum alloy

- Static Accuracy: 0.25% full scale or better

- Dynamic Accuracy: +/- 1% of full scale with leveling track (See Weigh in Motion)

- Dynamic Accuracy: +/- 3% of full scale without leveling track

- Overload Capacity: 200% full scale

- Input/output Resistance: 560 ohms +/- 50 ohms

- Stability: 0.5% full scale/year

- Ground level Requirement: <5mm within 0-4m

- Weight: 52 lbs including ramps, 42 lbs without ramps

- Operating Temperature range: -10 to +55 deg C

- Output: 0.6 to 1.0 mV/V

- Excitation: 5 to 24 VDC